|

|

|

#1 |

|

Polishing metal GBB Slides?

hey guys i was wondering if anyone knows if/how to polish the slide for my kjw gbb meu 1911. i want a silver look without buying a new barrel. can it be done and if so how would i go about doing it?

__________________

Loves me some CQB |

|

|

|

|

|

|

#2 |

|

You can polish any metal slide, the question is how long it'll stay that way. Easiest method is sandblast the slide to get rid of the paint and get it to a uniformly coarse finish, and start from ~200 grit sandpaper and work your way up to ~1000 or more, in 200-400 grit increment. Then finish with some kind of metal polish. If its like aluminum it should not be too bad with oxidizing(might get a bit dull after a while). But if its pot metal than it can get grey or black overtime as it oxidizes. You can use automotive clearcoat after polishing to seal the finish.

|

|

|

|

|

|

|

#3 |

|

Slow mo.

|

Why would starting at 200 be better than starting at say, 400? I'm curious, I know its the way to go, but wouldn't you also be removing more metal causing more play between the slide and the barrel with the higher number of sandings?

__________________

The ultimate measure of a man is not where he stands in moments of comfort and convenience, but where he stands at times of challenge and controversy. - Martin Luther King, Jr.

|

|

|

|

|

|

#4 |

|

A-56 aka Mr.Hitman

|

Going lower removes the scratches. You don't sand inside the slide anyways.

|

|

|

|

|

|

#5 |

|

Slow mo.

|

The OP said he didn't want to get a new barrel... so I thought he wanted to sand the barrel as well as the slide to create a complete stainless look from a uniform black look.

__________________

The ultimate measure of a man is not where he stands in moments of comfort and convenience, but where he stands at times of challenge and controversy. - Martin Luther King, Jr.

|

|

|

|

|

|

#6 |

|

Strelok polished the Slide on his 1911 to he point where we could use it as a signal mirror lol. I don't remember what he all used for sandpaper, But I do remember that he used Brass polish and it turned out great, hopefully he reads it and can give you a better anwser.

|

|

|

|

|

|

|

#7 |

|

Don't sand blast it.. Maybe use some paint stripper.. Sand blasting digs into the metal too much, and you'll find yourself sanding for WAAY too long.

__________________

|

|

|

|

|

|

|

#8 |

|

It depends on how well the original part is though. If I am refinishing a nicely machined slide I'd start from something finer. But if the part has thick paint on shitty metal, I'd definitely sand blast it because it takes forever to remove the paint and start from a uniform finish.

|

|

|

|

|

|

|

#9 |

|

DON'T DO IT!!

Sure the slide will look nice when you're done, maybe... assuming you put in the many hours of finger numbing time. I've done lots of slides and after every job, I wished I'd just bought a polished slide instead. If a slide costs $80–120 and polishing takes anywhere from 4–12hrs, what is your time worth man! Fagetboutid!

__________________

Retired — Freedom 35 |

|

|

|

|

|

|

#10 |

|

a.k.a. Palucol

|

Anybody ever thought about plating them?...... Will save lots of time and money! (i know you need special chemicals to plate potmetal, (a copper plating then after that you can plate anything over the copper coat...:P)) but you could always give it to a local platingshop and i'm sure they have all the correct chemicals! :P

Thats what I'm going to do once i get my hicapa.... Plate the safety lever, magcatch..... I'll update my postif the plating was successfull! |

|

|

|

|

|

#11 |

|

Have any of you guys used Aircraft paint stripper to rip paint off?

I've used that stuff on multiple Valve covers and it takes off paint no problem! I would try that stuff, But be careful with it!

__________________

|

|

|

|

|

|

|

#12 | |

|

Quote:

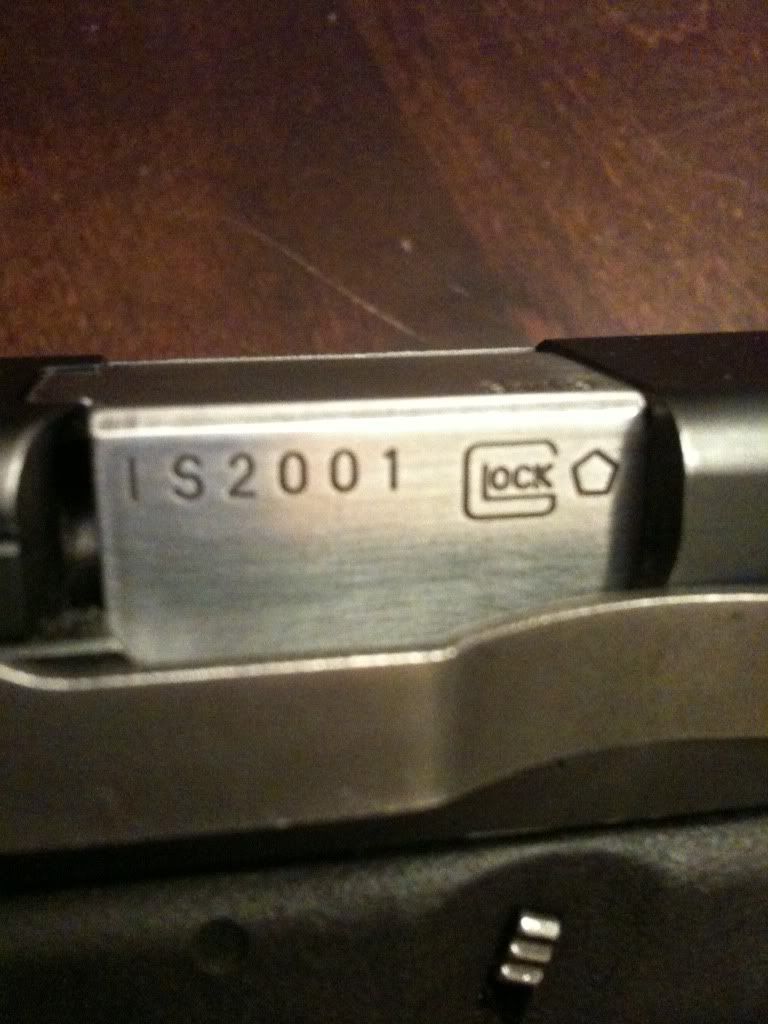

i did this, in 17 minutes two nights ago. from this...........  to this..............    i started with a "sand paper foam block" from home depot to get the paint off, and since it is foam, it gets the nooks and crannies well. then, 600 grit, in the same direction (as changing directions will provide unfavorable swirls) then 1000 grit, again, in one direction (back and forth if you must) then, a fast wipe down with fine steel wool, and BAM, done. i can see myself in it. now, if you really what a FULL MIRROR shine, use 2000 grit and wetsand it with WD-40 as a water replacement. i have polished MANY different things, and my process is fast, and VERY effective. see post # 135 here.... http://www.airsoftcanada.com/showthr...t=82506&page=9   from a post in the link in my sig, posted July 8th 2009.....

__________________

My KSC G26 Build My "As close to real steel" TM/KJW G26 Build My "Anti-Snag/Smooth" TM/KJW G26 Build THE BEST 1911 PARTS ARE SOLD HERE Last edited by MikeMcNair; February 13th, 2010 at 19:31.. |

||

|

|

|

|

|

#13 | |

|

Quote:

i keep Air Craft Stripper (ACS) in my tool chest at all times, and have yet to use it on the airsoft slides or barrels due to the fact that they are treated differently than say, a valve cover, or a car wheel. it should work, but my post above works so fast, i see no need to bring out the stinky stuff. ACS is awesome, don't get me wrong, but it is for larger, more serious projects in my opinion. i did that here.....     more mildly polished stuff, i didnt go mirror on these....            and, when you are done with the steel wool, tie a wire to it, and light it on fire, then spin..........  (sorry for all the pics, but i am a polishing whore, and will polish just about anything i can get my hands on.... |

||

|

|

|

|

|

#14 |

|

formerly Omega!

|

The main factors to remember when polishing GBB slides are cost (will you be buying a new slide? If so, might as well get a polished one from the start), time (how much free time do you have, remember that quality takes time and skill), and ability (if you don't feel confident in sanding, dipping, maintaining your slide, either just buy one, or practice on a plinker). Another thing to remember is that most metal slides are not made of stainless steel, and so will dull and oxidize when the paint is stripped and they are polished. This can be solved with regular maintenance and oiling (sealant, too, although I haven't tried any yet...), but it can still be a hassle if you don't like maintenance.

__________________

"History shall be kind to me, for I intend to write it." - Sir Winston Churchill |

|

|

|

|

|

#15 |

|

i recommend NUVITE or SPEEDY metal polishes for this.

|

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|