|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#1 |

|

WE GBBR Bolt Catch Fix (Magazine Mod)

I was having issues with the bolt not catching on an empty mag with my WE SCAR, here is my solution.

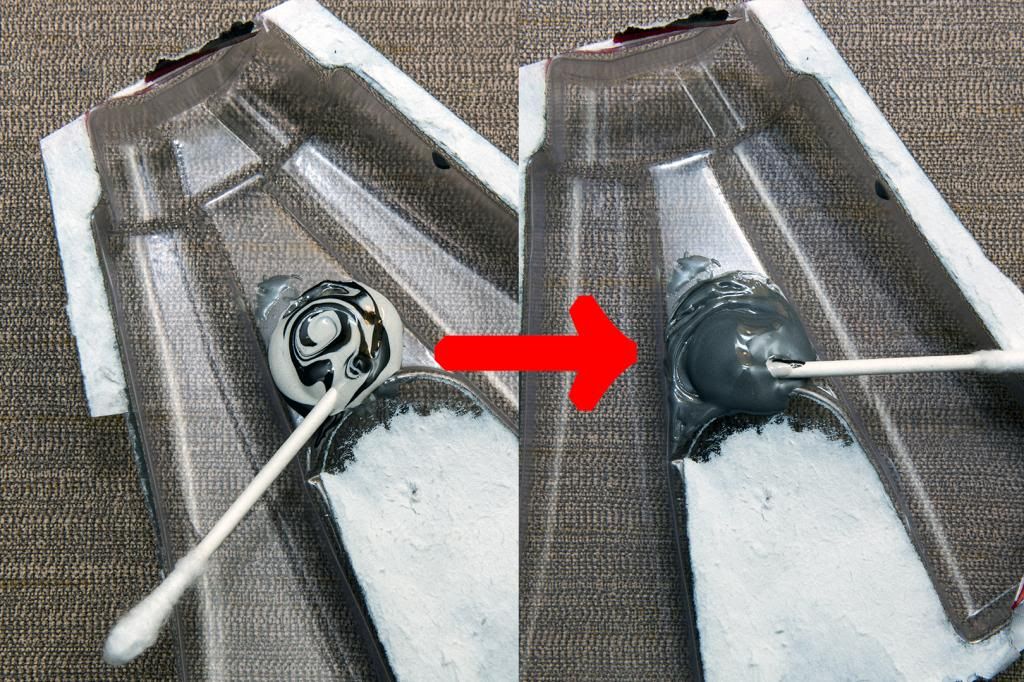

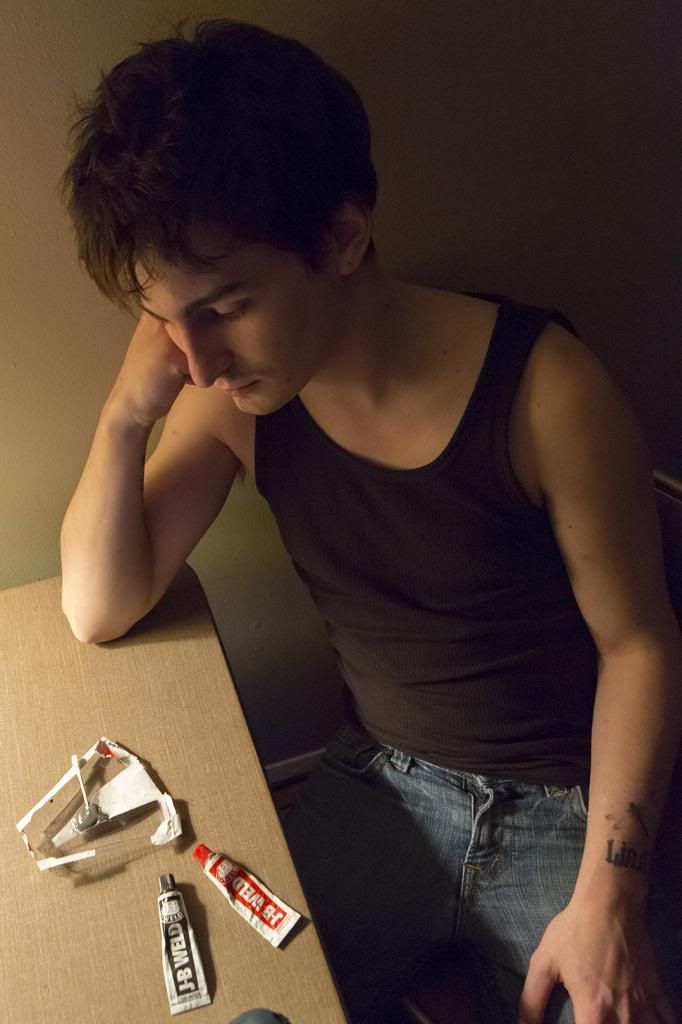

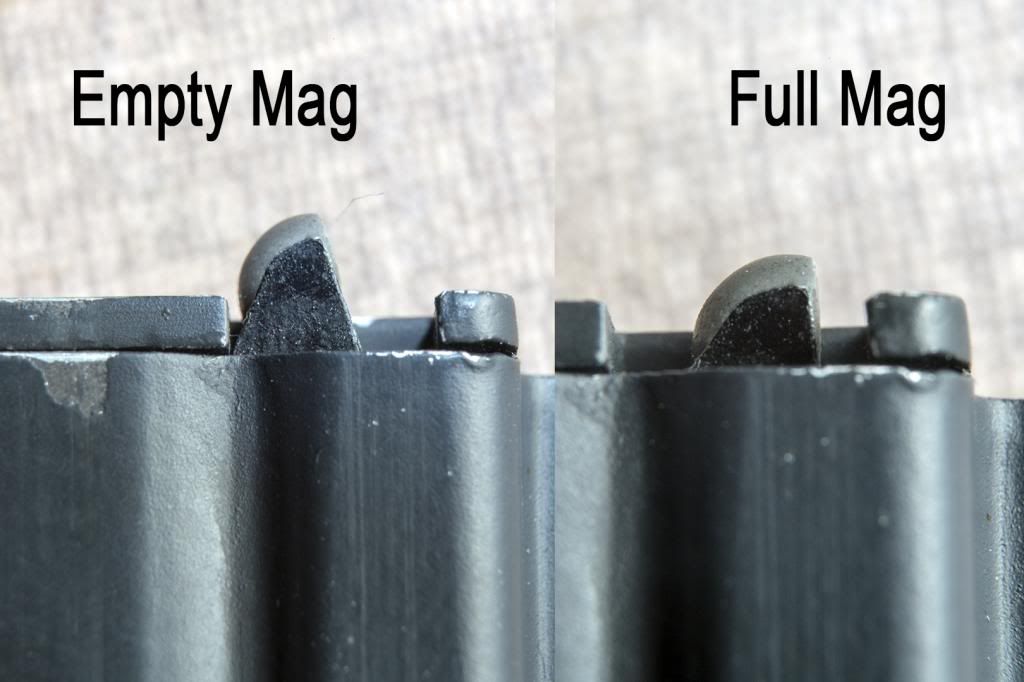

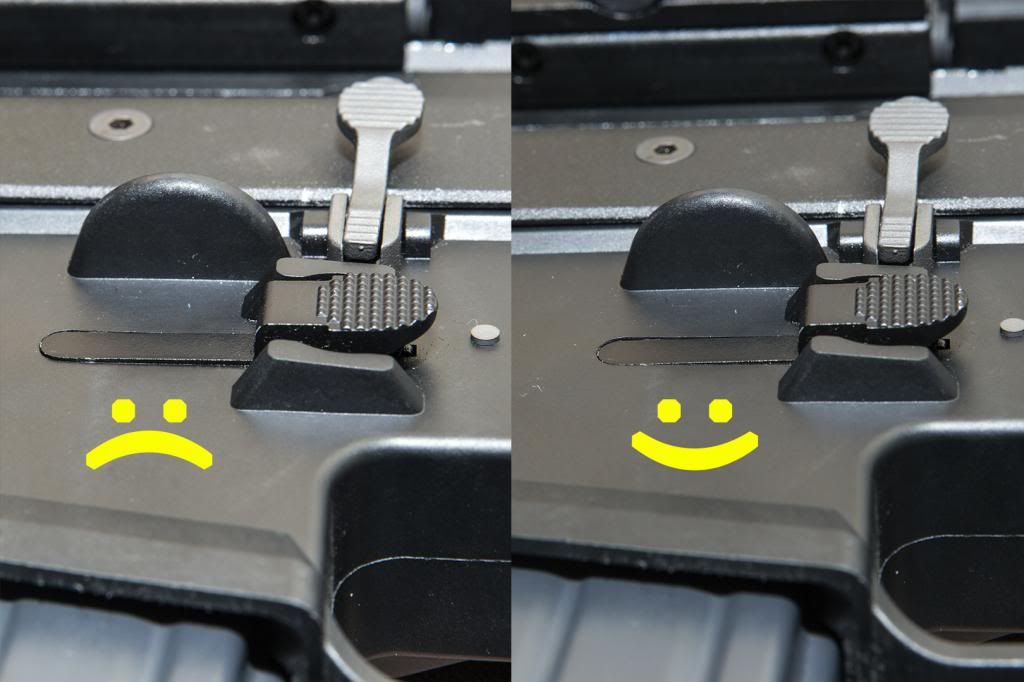

I'm not sure if the same fix will apply to other WE models, but seeing as the bolt catch mechanism is in the same place - I don't see why it shouldn't. (someone let me know) The problem lies in how the mags sit in the magwell. I noticed that if you push the mag forward slightly, the bolt catch would function. Therefore my solution was to eliminate the wobble and force the mag into a position where the pin/'nubbin' will always be high enough to engage the bolt catch (on an empty magazine). Required materials/tools: 1) JB Weld - can be purchased and any automotive/hardware store. 2) The plastic packaging for the JB Weld (don't toss that out!) 3) Dremel Drill (or likewise tool) 4) Small disposable stick-like object (I'll be using a Q-tip with the fluffy bit cut off) 5) Scissors  STEP ONE Use the scissors to remove a piece of the plastic JB Weld packaging. Save it, you'll need this later.  STEP TWO Mix the two parts of the JB Weld.  STEP THREE Wait for the epoxy to harden a bit, just so that it's not as liquid.  (You don't have to watch it harden) STEP THREE Apply a small drop of JB Weld onto the top of the little metal 'nubbin' that pokes out of the top of your magazine when it's empty. This will give the 'nubbin' a higher profile, and allow it to reach the mechanism inside the gun that engages the bolt catch.  STEP FOUR This is where that piece of plastic packaging comes in. Cut off a piece the same size as the opening on the side of your magazine.  STEP FIVE place the plastic bit inside the hole like so. (you may have to shorten it)  STEP SIX Apply small amount of JB Weld into the top of the hole.  STEP SEVEN Push the plastic piece forward so there's about 1-2mm of JB Weld between the plastic and the top of the opening.  The idea here is to add a bit of material to push the magazine slightly higher into the magwell - thus pushing the 'nubbin' slightly higher. This mod also has the side-effect of pushing the magazine into the nozzle assembly and creating a better seal. (BONUS!) STEP EIGHT This is the trickiest part of the operation. Wait for the JB weld to partially solidify - Then use another piece of the plastic JB Weld packaging to hold the JB Weld in place, while you remove the first plastic piece. (I usually lick the second 'retainer' piece so the JB Weld doesn't stick to it.)  STEP NINE Wait for the JB Weld to completely solidify. (I left mine overnight) STEP TEN Use your drill (or alike tool) to file down the drop of JB Weld so that when there are BBs in the magazine (or the dry-fire switch is engaged), the 'nubbin' fits inside it's hole and sits just above the top of the magazine. (Assuming your bold catch isn't functioning with the 'nubbin' is fully erect, It's doubtful that the milimetre that it sticks up when disenged should engage the bolt catch.) Your finished 'nubbin' should look like this.  STEP ELEVEN Use your drill (or alike tool) to file down the new edge you've created in the hole on the side of your mag so that the magazine fits in to the magwell (very snugly), and the mag release is flush with the lower receiver.   STEP TWELVE Test it. If the bolt still isn't catching then you may need to apply more JB weld to the 'nubbin' or the hole on the side of the mag. If the bolt is catching even when loaded with BBs or the dry-fire switch engaged - file off a bit of the JB Weld off the 'nubbin' If the bolt catch is functioning properly - Yay! END This modification requires a small amount of trial and error, but it's worked on all of my magazines. None of them would engage the bolt catch, now they all do.  Hopefully this can be of help to someone out there. This was my first tutorial, I'd appreciate any feedback you can give me.

__________________

Last edited by Trekkie420; December 13th, 2012 at 11:37.. |

|

|

|

|

|

|

#2 |

|

a.k.a. wingmantank

|

not sure if its a good idea to modify on the mags...in case people like me have 12+ mags it would be a PITA to do, I 'l just simply modify the bolt catch and mag release lever. well, just IMO.

__________________

|

|

|

|

|

|

#3 | |

|

Quote:

The problem lies in how the mags sit in the magwell. I noticed that if you push the mag forward slightly, the bolt catch would function. Therefore my solution was to eliminate the wobble and force the mag into a position where the pin/'nubbin' will always be high enough to engage the bolt catch. I did try the mod you suggested (assuming you mean adding to the bottom of the lever so it's closer to the pin/'nubbin'), it was actually my second attempt (after the blob of JB weld on the pin/'nubbin'). It worked for most of my mags, but would still fail occasionally. This option although it may work, doesn't really fix the problem that causes the malfunction - the mags being slightly loose in the magwell. Though if that solution works for all your magazines, it's a much easier option, you're definitely correct there. Modifying the mag release would probably fix the wobble, alas; I thought it would be easier to modify the mags. (was in no rush to start adding blobs of JB weld into my shiny new GBBR just yet.)

__________________

Last edited by Trekkie420; December 13th, 2012 at 11:40.. |

||

|

|

|

|

|

#4 |

E-01 E-01 |

+1 t@ank

It's the right idea but modifying the bolt catch is a lot easier. I have a couple of WE M4s and one worked fine (the 2nd one, purchased later) while the first didn't. Comparing the two bolt releases, I could tell the one that didn't work (early Open Bolt) was different and looked manually dremelled instead of being made the right shape/size like the later model. I ended up getting an unmodified closed bolt bolt catch and dremelling it myself, using the good one as a size guide. But the alternative would have been adding some material to the surface like you did, and then just smoothing that down to size with the dremel. Looking at the SCAR bolt catch I think that could be done easily.

__________________

|

|

|

|

|

|

#5 |

|

+1 on modding the bolt catch. I've done that a few times now and it's much easier than modding all the mags. Plus, it's easier to do.

__________________

Please email me as I'm not on ASC too often.  Custom Build | Upgrades | Repairs | Maintenance Contact: ghostgunwork@gmail.com / Private Message |

|

|

|

|

|

|

#6 |

|

Step one: Buy RS mag catch.

Step two: Install. (Might require some filling, take your time!) Step three: ??? Step four: Profit! Seriously, it's a lot easier to replace the cheap pot-metal mag catch with a steel one. |

|

|

|

|

|

|

#7 |

E-01 E-01 |

For the mag catch yeah, but the RS bolt catch won't fit. Not even made the same way.

__________________

|

|

|

|

|

|

#8 |

|

For modding the bolt catch on the WE m4, you just need to shave off some material on two parts, I've converted numerous closed bolt catches to work properly on open bot systems, the problem with JB weld is that overtime, it wears out and needs to be reapplied again.

|

|

|

|

|

|

|

#9 | |

|

Quote:

The option of adding JB Weld to the bolt catch itself will fix the malfunction, but it doesn't address the issue that caused it. Also; on the note of JB Weld wearing down; I agree completely. That's why I try to keep it on external parts, as GBBRs have a habit of turning soft metals into fine powders mixed with lubricants. The most logical option would be to modify the magazine catch so the mag sits higher in the magwell. The only reason I didn't do this is that it seemed like it could be a tiresome procedure; pulling the latch out, modifying it, putting it back in, testing it, pulling it back out making adjustments. If anyone has done this I'd love to see some pics of the final product.

__________________

|

||

|

|

|

|

|

#10 |

|

KullWarrior's AEG shim method worked the best for myself. It's incredibly easy and for the price of shims, can't go wrong.

|

|

|

|

|

|

|

#11 |

|

^^^

I've had good results with the shim method as well. |

|

|

|

|

|

|

#12 |

|

I did see a handful of WE in my little workshop lately and I've always glued a shim under the bolt catch lever and it works awesomely, bolt catches 10/10 and feels nice and crisp.

|

|

|

|

|

|

|

#13 |

|

aka coachster

|

Glue a metal shim will work 100% with all mags including buddy mags....Unless you are going to mod all of your friends mags as well!

|

|

|

|

|

|

#14 |

|

I must have made the shim too thin when I did it then, seeing as it worked for everyone else.

How thick should thine shim be? Oh well, at the least my mags fit solid in the well now. No wobble at all.

__________________

Last edited by Trekkie420; December 16th, 2012 at 02:36.. |

|

|

|

|

|

|

#15 |

|

Green Synergy

|

AEG shim worked wonderfully when applied with a shorter spring and some superlube.

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|