|

|

|

#1 | ||

|

http://www.airsoftoutletnw.com/dange...-ns2-cqb-valve

Quote:

I hope it's not a mistake on their behalf since I ordered a few to fit on my MK23 and USP Tactical.

__________________

Quote:

|

|||

|

|

|

|

|

#2 |

|

Does anyone have a better pic? The machining on that valve looks rough.

|

|

|

|

|

|

|

#3 |

|

The part just replaces the flute valve in the nozzle. The one that comes in the KSC guns meant for the Japanese market looks just like this to reduce the FPS to a legal limit.

I don`t have this, I have an RA-Tech NPAS, but when the NPAS is completely closed it looks just like this and my gun shoots 330 FPS. The Dangerwerx valve will do the same. However, I cannot tell you if the size of the one in the MK23 is the same as in the MP7, but the rocket/flute valve in my MP7 looked oversized from what I remembered, to the one I found in my KWA G19. actually, upon further inspection of the KWAUSA website the flute valve/jet nozzle says that this is the replacement part for all NS2 guns: http://store.kwausa.com/partsns2aluminumjetnozzle.aspx So i'd assume that this dangerwerx valve is going to work on your MK23 and USP if it's a NS2 system. |

|

|

|

|

|

|

#4 | |

|

They're kinda expensive for $20 each for a metal nipple but what can you do?

Was hoping to drop fps to appropriate level instead of having to buy a new pistol.

__________________

Quote:

|

||

|

|

|

|

|

#5 |

|

$20 bucks looking like that? Does anyone have one cheaper?

|

|

|

|

|

|

|

#6 | |

|

I bet someone here can make it...it looks pretty straight forward

__________________

Quote:

|

||

|

|

|

|

|

#7 |

|

Harvester of Noobs' Sorrow

|

lol wow.. $20 for that.. i have made one my self for an MP7. takes 10min to make. that would take literally 5-10 sec to make on a CNC lathe, $20 is ridiculous.

i made mine out of 6061 T6 bar stock, and could easily make many more for half that price.

__________________

Weapons Technician / Gunsmith Don't look at me, I don't know, lol ¯\(°_o)/¯. Last edited by Dynamo; November 12th, 2012 at 01:53.. |

|

|

|

|

|

#8 | |

|

If you want one to make a copy of let me know, we airsofters need a price break

__________________

Quote:

|

||

|

|

|

|

|

#9 |

|

Harvester of Noobs' Sorrow

|

i have a PTP P226 and access to their MP7, so it's easy enough to make. i'll make a few tomorrow and post some pictures, see what you guys think.

__________________

Weapons Technician / Gunsmith Don't look at me, I don't know, lol ¯\(°_o)/¯. |

|

|

|

|

|

#10 |

|

Harvester of Noobs' Sorrow

|

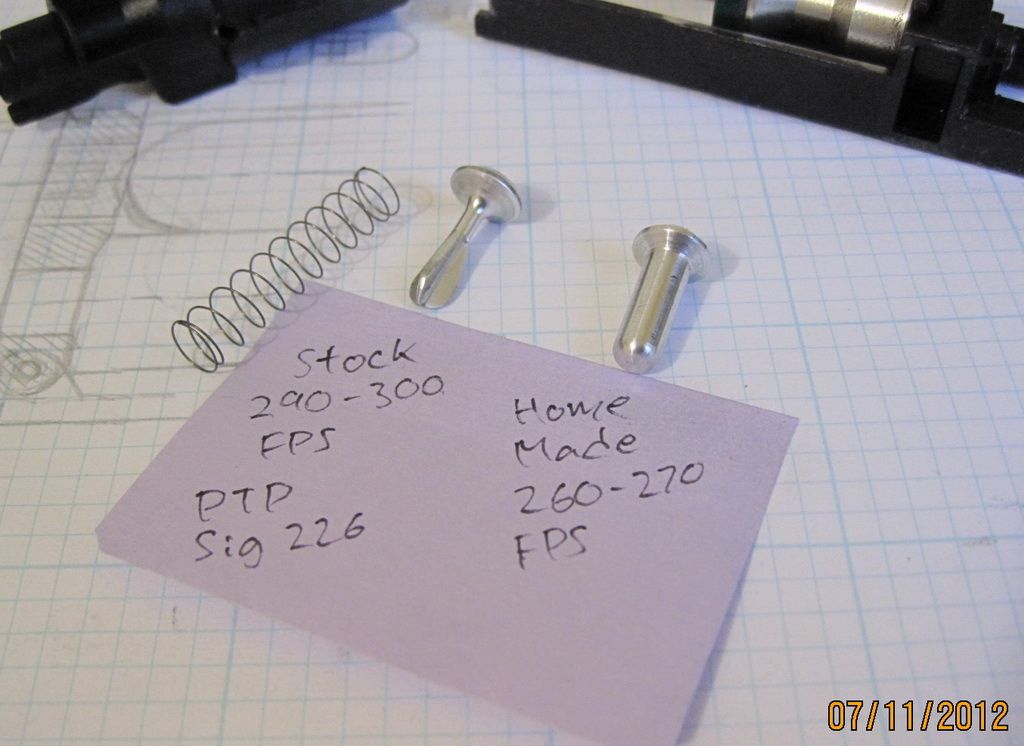

well here we go.

took me about 30 min to make including set up. i don't see a need for a steel valve, as we would want a valve that is as light as it can be so it can do its thing as fast as possible. the RA-Tech NPAS valve is half aluminum and half steel (the part that adjusts), and it is heavy. so much so that the inertia of its return to the open position due to not only its return spring, but also from the weapon's recoil, that it brakes the cross pin that holds the valve in the cup. a few weeks ago i made a custom valve for my buddy's stock MP7. it was shooting around 350 fps with the stock valve, but with my valve it is now 390+ fps. thats with the stock barrel. anyways, here's a pic of the test valve next to the stock one. i think i'll try and make it super light by drilling down the back along its length, and leave it with just a thin wall down the shaft. i also noticed that the stock valve's flute is not machined. looks like it was machined down to a straight cylinder shape then put into a press to form the flute.

__________________

Weapons Technician / Gunsmith Don't look at me, I don't know, lol ¯\(°_o)/¯. |

|

|

|

|

|

#11 | |

|

ooo I like, I wouldn't mind my pistol shooting 260-270 for CQB...

__________________

Quote:

|

||

|

|

|

|

|

#12 |

|

Harvester of Noobs' Sorrow

|

im gona make another one as a high flow one and see how high i can get the FPS. would be nice to get a good out door pistol also

__________________

Weapons Technician / Gunsmith Don't look at me, I don't know, lol ¯\(°_o)/¯. |

|

|

|

|

|

#13 |

|

Hah, that's pretty cool. =)

I know someone who needs to slow down his KWA M93r in the coming weeks. If you make some more, I'd love to come by and buy one |

|

|

|

|

|

|

#14 |

|

Tys

|

Nice Dynamo

While it would be stronger to hollow out the float valve as you described you could also turn down the most of the body of it to reduce diameter/weight. As long as it starts into the nozzle tip it'll self center and close off the gas flow. The ones I made were brass and soft-ish aluminum...they work ok but the brass is way too heavy as a solid slug, shiny though. |

|

|

|

|

|

#15 | |

|

Harvester of Noobs' Sorrow

|

the wide shaft is how the FPS out put is reduced. thats why is suggested to hollow it out. granted there are two main ways of adjusting the FPS. either restrict the flow by increasing the diameter of the shaft, or increase the distance of the valve sealing surface from the loading nozzle tube. the high output valve im making now will have flutes and will also have the valve sit a bit further back. i am also inserting a high density plastic inside the back side of the valves as a strike surface for the cross pin, so it wont ding up the back of the valve.

Quote:

__________________

Weapons Technician / Gunsmith Don't look at me, I don't know, lol ¯\(°_o)/¯. |

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|