|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#556 |

|

I am also still trying to fix this inner barrel problem. I am still wondering what exactly is part 117. On a scar 117 is a screw. I'm guessing it's the head of the n-pas kit that has the three o-rings. So basically the problem is the red highlighted tip shown in the pic above is not lining up squarely with the inner barrel? So the bb gets pushed into the inner barrel at an angle? So the plan is to file it so the angles match perfectly. I don't know if I'm making any sense. I'm really hoping to have this piece of shit running for summer.

|

|

|

|

|

|

|

#557 |

|

A-56 aka Mr.Hitman

|

I have an issue with my WE M4, as some of you know the front has a DD MK18 rail. Now the problem is that the barrel wobbles.. I haven't abused it, and haven't gone to a game in months.

I wanted to take it out to a game after I zero it but now the barrel wobbles. I'm pretty sure I move the gun from one corner to the other and leaned touching the silencer.. So now, I wiggle the barrel and it moves. I tightned the barrel nut, yet I still have wobble. The whole barrel moves, and I look in the chamber, the gold brass tube moves with the outer barrel too.. Any help? |

|

|

|

|

|

#558 |

|

Division

|

Take the barrel nut off and check to see if the receiver is fractured at the threads.

__________________

Weee! |

|

|

|

|

|

#559 |

|

are you running a low profile gas block with the DD rail

I had to run a low profile gas block for it to make the barrel stable and not wobble |

|

|

|

|

|

|

#560 |

|

pɹıq spɹɐʍʞɔɐq

|

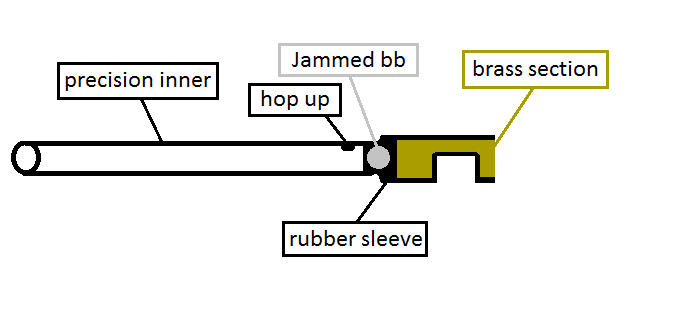

I have the WE HK 416, and ever since I installed the NPAS kit, I am having the BB jamming issue that other people have when they change the inner barrel (I didn't change mine). I am quite new with GBBR (still don't know how to adjust the hopup on this thing), but I didn't change anything but the NPAS.

Here is Ross' image describing the problem, so the question is anyone solved the issue yet?

|

|

|

|

|

|

#561 |

|

well. I'm going to take the npas out and put the original nozzle back in. Maybe it's just the npas that conflicts with the precision inner. If it fires then I'm pulling out my jewelers files and going to start experimenting.

|

|

|

|

|

|

|

#562 |

|

Tys

|

Barrel wobble....you need spacers between the out flange of the barrel and the retaining nut to take up the space. A mix of metal shims and a hard rubber o-ring will take out the play and allow for some relief from the shock/impact/vibration. The stock WE's come with on O-ring there...it's there for a reason.

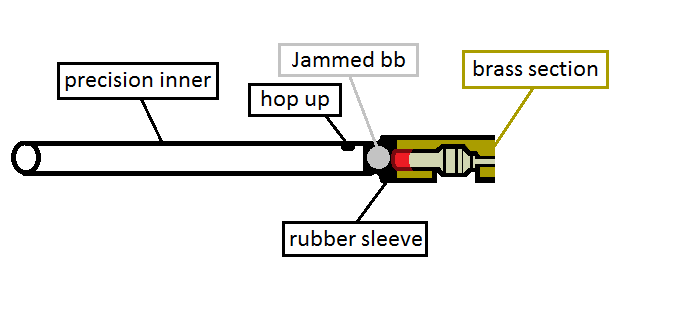

Jamming...several of the last RATech NPAS nozzle bodies that I've mic'd have been slightly oversized. The stock ones are a tight enough fit...the RATech ones are a jam fit. This causes things to hang up. Swap back to stock nozzle...or take 400/600 wet dry paper and reduce the diameter of the tip of the nozzle to be a good fit with your chamber. Takes 3-4 tries (test fit as often as you need) and about 5-10min of sanding. Apply even finger pressure to both sides of the nozzle "pinched" between the emery paper while you turn the nozzle back and forth....stop and turn 30deg every couple of turns to get an even reduction in diameter...you can use finer paper (i.e. 1200+) or whatever to buff its finish smooth. The key with this method is to get a feel for how nice a fit is good but not too tight. |

|

|

|

|

|

#563 | ||

|

A-56 aka Mr.Hitman

|

Quote:

Quote:

Like I lock the nut as tight as I could, then wobble the barrel with the rail off, then I throw everything back together, and I give the barrel a bit of pressure to any side, then it starts to wobble... EDIT: Tys, I never removed the stock rubber o-ring from the barrel... Do I need more? It's not damaged.. Last edited by Shirley; January 10th, 2011 at 14:45.. |

||

|

|

|

|

|

#564 | |

|

Quote:

|

||

|

|

|

|

|

#565 | |

|

Quote:

Last edited by spartan117; January 10th, 2011 at 17:41.. |

||

|

|

|

|

|

#566 |

|

Ok. So the area I need to sand is the red area in the picture below, correct?

How much of it should I sand? 1/4 inch from the tip?

|

|

|

|

|

|

|

#567 |

|

8=======D

|

You want to reduce the diameter .. not the length.. and to fit so that means .. sand a bit and check .. sand a bit more check again

__________________

Brian McIlmoyle TTAC3 Director CAPS Range Officer Toronto Downtown Age Verifier OPERATION WOODSMAN If the tongue could cut as the sword does, the dead would be infinite |

|

|

|

|

|

#568 |

|

Oh, yes. I should have been more clear. I knew he meant diameter. But do I need to shave off the diameter equally 1/4 inch down, or just the tip or something? Man, this is hard to word. Does the npas need to be skinnier everywhere or just near the tip?

|

|

|

|

|

|

|

#569 |

|

I am building a 2nd upper for my m4. So far i have the upper receiver, outer barrel, gas block, gas tube, and all parts for the rail system. I am getting a brass tube and parts for the hop up. It will be a close bolt system.

My question is, what parts are included in the ra-custom package, such as the one here: http://www.ratech.com.tw/store/produ...?id_product=83 I would like to make sure about this before ordering other parts I am going to order. Last edited by faithless; January 10th, 2011 at 19:40.. Reason: To make the question more clear |

|

|

|

|

|

|

#570 | |

|

A-56 aka Mr.Hitman

|

Quote:

Installing the original delta ring with the DD rail? That wouldn't fit... |

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|