|

|

|

#16 |

|

Bloody well done. Any progress?

__________________

|

|

|

|

|

|

|

#17 |

|

Unfortunately, my SCAR is still in my friends house, getting tuned up

When it comes back, I'll try to design the front of the stock (where its mounted on the gun) and update all the dimensions to get more realistic look. When the model's ready, I'll try to find a way to manufacture it, I guess CNC milling will be the cheapest and most durable way (3d print is still WAY to expensive and not that strong after all). If anyone would be interested in buying the stock when it's ready, please give me feedback how much you'd pay for it. When it comes back, I'll try to design the front of the stock (where its mounted on the gun) and update all the dimensions to get more realistic look. When the model's ready, I'll try to find a way to manufacture it, I guess CNC milling will be the cheapest and most durable way (3d print is still WAY to expensive and not that strong after all). If anyone would be interested in buying the stock when it's ready, please give me feedback how much you'd pay for it.

|

|

|

|

|

|

|

#18 |

|

Very nice work sir. You live in Warsaw?

__________________

"Strength and Honour, Faith and Fury. In these four principles is Life defined and Victory achieved." https://www.facebook.com/pages/Bad-K...8&ref=bookmark |

|

|

|

|

|

|

#19 |

|

3D print it, make a mould, and then make copies out of fibreglass.

__________________

SuperCriollo |

|

|

|

|

|

|

#20 |

|

Let's see the prototype.

Are you going to have a cavity for a battery? |

|

|

|

|

|

|

#21 |

|

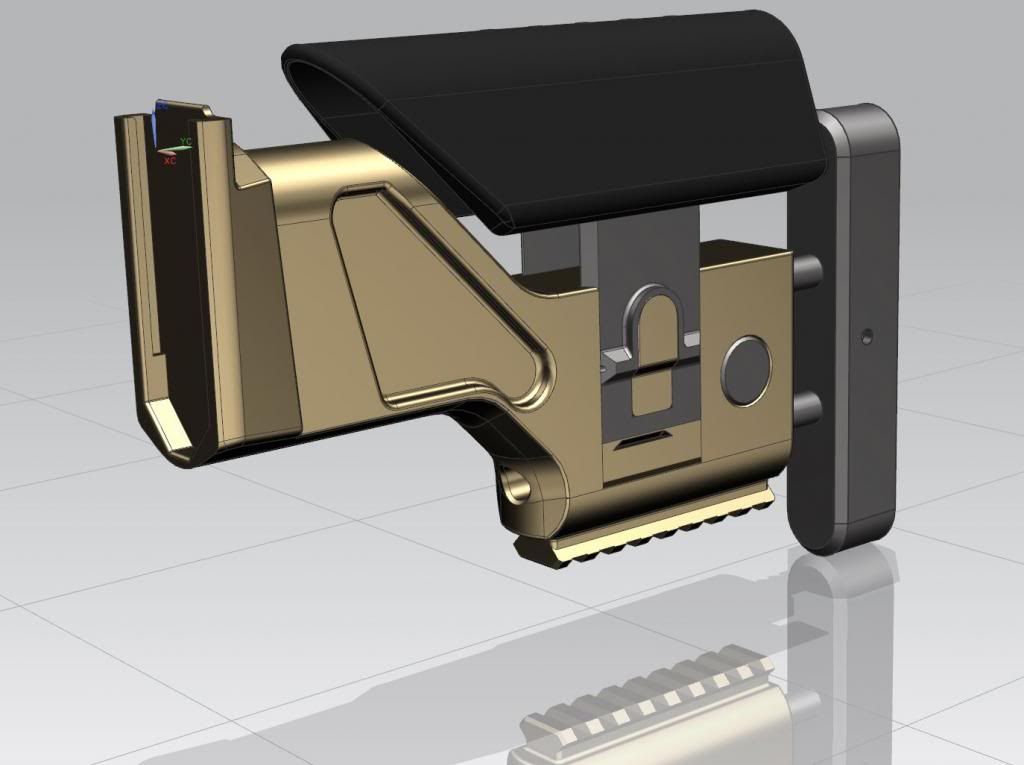

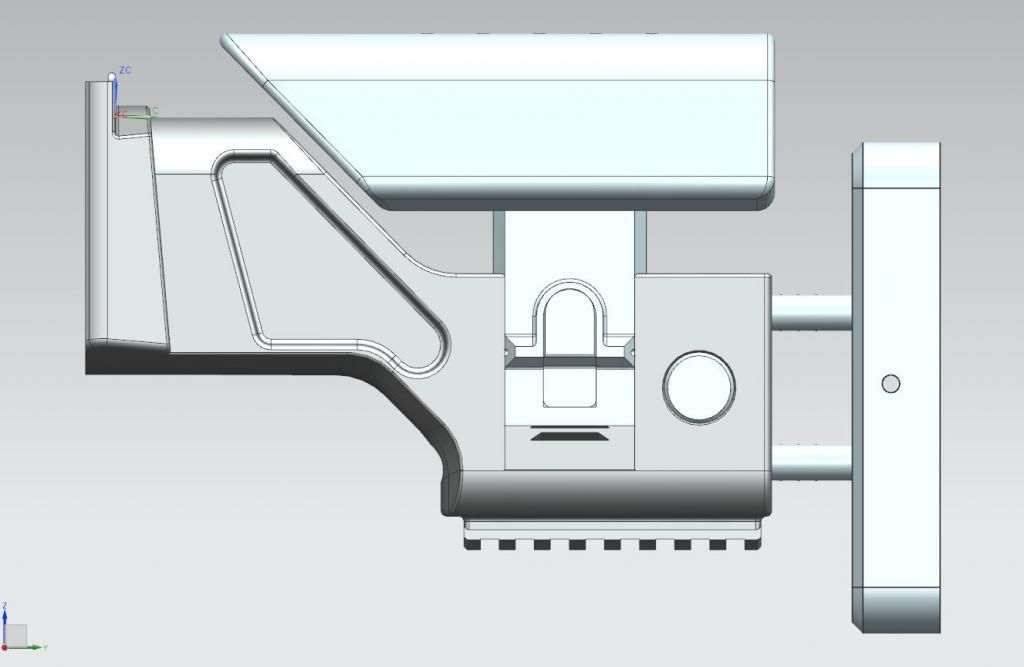

My rifle just came back so it was about time for me to get back to the project. I've updated the dimensions so that the stock is at the moment almost ready to be printed in 3D. I've also added a Picatinny rail to the bottom of the stock, because current issue Mk 20 has got a rail as well (from what I found on the web). About the battery - I thought about trying to squeeze some room for battery, but honestly I don't think it will fit there in any possible way - there are too many holes and cut-outs in this design to accomodate even the smallest LiPos (except pistol ones, but thats not an option anyway). So no, at this point I think installation of this stock will require you to rewire your GB to the front and use some sort of PEQ battery box.

Let me guys know what you think  Any suggestions concerning a cheap easy to rapid prototype it are most welcome! Any suggestions concerning a cheap easy to rapid prototype it are most welcome!

|

|

|

|

|

|

|

#22 |

|

First, being in the 3D world myself, I can only say "Nice" because I know how it is to model without a lot of references.

Now, I don't know how CAD softwares handle the perspective, but your model seems a little stretched in the "Y" axis or up ("Z" axis if we speak about 3ds max). Maybe a side view could help. For the battery, there are some small, flat lipo batteries sold at HobbyKing. Not the strongest, but they could fit in there in diagonal, sliding from the top between the stock connection and cheek thing. 100x7x35 per cell, which means 100x14x35mm for a 7.4 volt. I'm sure it would fit. Also, what's the usefulness of the rail at the bottom :P? |

|

|

|

|

|

|

#23 |

|

The rail at the bottom looks like its adapted from the Magpul PRS stock to accommodate a Magpul mono-pod (don't think its magpul forgot the company that makes those mono-pods)

Keep up the good work! The stock looks solid.

__________________

"Strength and Honour, Faith and Fury. In these four principles is Life defined and Victory achieved." https://www.facebook.com/pages/Bad-K...8&ref=bookmark |

|

|

|

|

|

|

#24 |

|

Company that makes nice monopods that I know of is Accu-Shot.

http://www.accu-shot.com/catalog/ind...m9heemojfbo970 About the LiPos - I know about those batteries, I've considered it, but since my SCAR is currently running 535 fps, my battery needs to be a bit bigger  But there's no problem for me to make some sort of hole in the stock if someone in the future would like to put a small lipo there. But there's no problem for me to make some sort of hole in the stock if someone in the future would like to put a small lipo there.First, the side view:  Now let me explain myself :P I've modeled the stock after this photo: http://3.bp.blogspot.com/_eRPHqoaA9g...0/SSR_2010.JPG with obvious changes to the design required to keep the rigidity when 3d printing (I kept the cutout from the original MK20 stock and changed the bottom of the stock where the rail is). I've just resized this photo on my screen so that the dimensions fitted my SCAR and took measurements off the screen  For the mounting plate I measured and copied the mounting solution from the standard stock. On my screen the stock is around 200mm long, my stock is exacly 195.5 mm long, so thats about right. Height of the mounting side cannot be altered - it's exacly as high as the standard one, 81.8 mm. Maximum height of the stock (top to bottom) is 121.4 mm. On the photo its around 120 cm, depending on how you look on it. I think it's quite correct, but I don't say it's 100% correct - it never will be unless I get my hands on the real one :P For the mounting plate I measured and copied the mounting solution from the standard stock. On my screen the stock is around 200mm long, my stock is exacly 195.5 mm long, so thats about right. Height of the mounting side cannot be altered - it's exacly as high as the standard one, 81.8 mm. Maximum height of the stock (top to bottom) is 121.4 mm. On the photo its around 120 cm, depending on how you look on it. I think it's quite correct, but I don't say it's 100% correct - it never will be unless I get my hands on the real one :P

|

|

|

|

|

|

|

#25 |

|

"bb bukakke" KING!

|

is it possible at this point to project the cost of producing these things? cause the boot is the only thing really keeping me from buying a scar.

__________________

I futz with V2s, V3s and V6s. I could be wrong... but probably, most likely not, as far as I know. |

|

|

|

|

|

#26 |

|

I see. Looks like you did your homeworks, looks right from the side.

For the lipo, that also makes sense. These lipos work well with a normal setup, but with a DMR you sure want something stronger. Now, I don't know how to make a prototype for that, unfortunately. |

|

|

|

|

|

|

#27 |

|

Well, about the costs: Cheapest DIY 3D printer that people recommend would set me back for around 600-650 US $. Then the material (PLA) is pretty cheap, around 20$ per kilogram (I estimate this stock would use no more then 0.5 kg, I know the density of PLA and the volume of the model). But I'm pretty far from buying this printer right now, simply because I don't have that money at the moment. That may change in upcoming months, so it will be a goal I'd be striving for

As for 3d printing it in a company which does such things - lowest price I've found quoted me for 107 euros just for the main body of the stock, so I'd estimate the whole stock would set me back around 200 euros with shipping and stuff. I don't want to spend that kind of money on the first pre-alpha prototype :P Simply because I'm already sure there will be several changes in the model before it's finally ready to use and use comfortably. That's why I'd like to have my own printer/access to a printer. Of course I'd let you guys know when this stock would be buyable  Battery issue still gives me nightmares, I don't know what to do with it to make it look nice (without a giant PEQ) and still have enough power to make the gun run smooth... Battery issue still gives me nightmares, I don't know what to do with it to make it look nice (without a giant PEQ) and still have enough power to make the gun run smooth...

|

|

|

|

|

|

|

#28 |

|

Why not CNC it instead...

A "cheap" tabletop CNC is around 600$ too, but can work on machinable wax just like aluminum, so you don't have to find a place to make the real thing once your proto is done... I think it would be a lot cheaper both for testing and production... you could make a single positive of the ABS/polymer part, then make a mold with silicon and cast as many as you want. And make the aluminum part out of a stock directly. In a few months I would be able to help with that, but I don't have mine just yet... |

|

|

|

|

|

|

#29 |

|

Sure, CNC is miles better, but you need to program the damn machine, something you cannot learn that easilly. But, I guess that you implied that you know how to do it with your message, so you could prove me wrong.

|

|

|

|

|

|

|

#30 | |

|

Quote:

You don't have to program in G-Code anymore... the software does that for your. You only have to set your tool size and path, then off it goes. |

||

|

|

|

|

|

||||||

| Bookmarks |

|

|

|