|

|

|

#46 | |

|

Quote:

there is only suppose to be one spring in there. the other side has a bigger notch so the second spring wont fit in there unless you cut it to length.

__________________

"May you fight with the strength of ten full grown men." |

||

|

|

|

|

|

#47 |

|

plus there's no groove in the top of the nozzle. So even if you're not sure which side the spring is supposed to be in, it only fits on the one side. If you put in the wrong side the spring would not sit flush with the BBU.

When I first took mine apart and re-assembled it I thought I was going crazy too when I only found one spring! |

|

|

|

|

|

|

#48 |

|

NAAZ's #1 fan!

|

After inspection you are both correct. One of the groves has a small peice that would interfere with the springs function if yada yada we all get it.....

Time to drain my bank account on upgrades now. Installed a systema inner barrel today. Works quite well. Noticed you didnt have this one on the initial list. -alex |

|

|

|

|

|

#49 |

|

Hi guys,

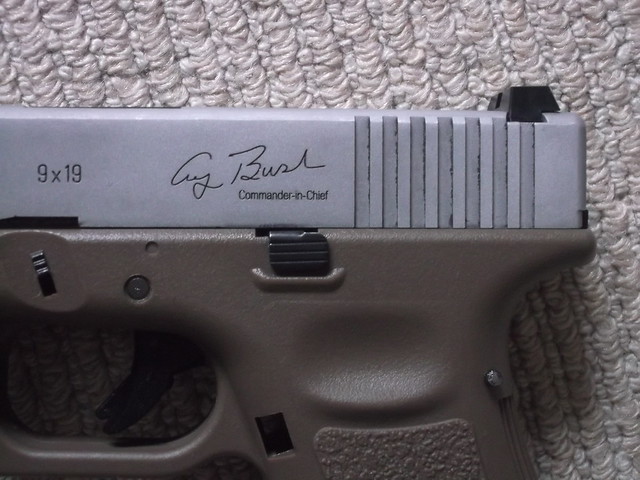

I have recently acquired a Glock 17 with Guarder frame and NWO Commemorative Slide. However I am having issues with cycling. I have cleaned and lubed everything but the slide just won't cycle smoothly. It appears the BBU is getting caught on the hammer bearing and the bit in front of the bearing. Sometimes the slide will go all the way back and forward, resetting the trigger. Other times it won't go all the way back and you have to cock the slide to reset it. I have tried to file the bit of the BBU which comes into contact with the hammer but it is has only improved it slightly and i'm not sure I feel comfortable removing anymore. Does anyone have any advice? |

|

|

|

|

|

|

#50 |

|

Was your glock well used before you installed these parts? Can you open it up and take a picture where the top and lower meet?

Do you have any other upgrade parts in the gun? Recoil Spring? Hammer spring? The stock recoil spring may not be strong enough to return the slide back to battery, and an upgraded hammer spring may cause additional pressure to the blowback housing causing the slide stick. |

|

|

|

|

|

|

#51 |

|

Thank you for the reply. I actually got the Glock second hand so I am not sure but there appears to be a little wear. The slide an frame seem quite new. I will get some pictures very shortly to show you. I believe apart from this the Glock is standard TM.

|

|

|

|

|

|

|

#52 | |

|

Quote:

You'll need to sand to it down to eliminate any possibility of any friction occurring. I've run into the same problem with that specific slide and sanding both areas fixed it. For the most part, the hammer bearing is quite easy to retract. It should spin and being a circular object, shouldn't catch onto your BBU provided it's properly lubed. It should "roll" along your bbu. You can switch to a smaller hammer bearing but you'll have trouble getting the sear to lock onto your hammer even if it cycles fully with a smaller bearing. Thus the result of this is the hammer staying uncocked at all times. Do everything that p.phresh said. Install the hammer springs correctly and all that jazz. and if your still having problems, sand the slide where I've told you.

__________________

"May you fight with the strength of ten full grown men." |

||

|

|

|

|

|

#53 |

|

Thank you guys,

I have some pictures here (albeit not very good ones) which shows where the slide is sticking:   Note the gap between the slide and frame here. It seems as though the hammer is pushing the slide upwards as it comes back.  (I forgot to put the hammer screw back in but it did it with it in anyway)  You can where I filed here. That is where it looked and felt like it was catching. I also have a video here aswell if that helps: http://youtu.be/PKWH9yfLEpE I will look at getting an enhanced recoil spring too and sand around the slide rails and see what happens. Thanks again for your help, mucho appreciated! Last edited by Mobot; August 13th, 2012 at 13:54.. Reason: More info |

|

|

|

|

|

|

#54 |

|

One more thing. I have not got a mag catch spring and it is the hardest part to acquire, ever. I was just wondering if someone would be so kind as to take a picture of their TM G17 mag release spring and provide measurements for it as I think I am just going to make my own. It would be HUGELY appreciated.

I must say this thread has been mighty helpful. Big thanks to all, especially e-luder for the write up. |

|

|

|

|

|

|

#55 | |

|

Quote:

for the mag catch spring, you can order replacement springs online. MAG makes one amd contains all the little springs including what you are looking for. google, my friend. Google.

__________________

"May you fight with the strength of ten full grown men." Last edited by e-luder; August 13th, 2012 at 16:23.. |

||

|

|

|

|

|

#56 |

|

My buddy just put in an order with WGC and I got a Guarder enhanced recoil spring, AIP 8mm hammer bearing and a MAG replacement spring set which i ordered for a different reason. However the set doesn't seem to include the mad catch spring? I have literally googled forever trying to find one!

|

|

|

|

|

|

|

#57 | |

|

Quote:

Anyways, I found it. Just google harder. Since your not Age verified, I can not disclose the direct link to the part as it goes against forum rules. Sorry man.

__________________

"May you fight with the strength of ten full grown men." |

||

|

|

|

|

|

#58 |

|

Lol. Ah man that sucks! I'm from the UK aswell so I cant be verified. Can I ask, is it called a mag catch spring or a mag release spring? Even searching for the part number (G17-28) comes up with nothing!

|

|

|

|

|

|

|

#59 |

|

I had the same problem with my guarder slide, will be staying away from them if I do get another Glock. I fixed mine by sanding the BBU, but only enough that it was still able to push down and lock the hammer. I stripped all the internals from the slide leaving only the BBU and I manually cycled the gun with my hand to identify the exact contact point causing the drag. I sanded it slowly until I got the smoothness I desired. I also sanded the lugs on the frame and polished them to ensure that minimal friction was present and used 2 recoil springs together.

The other thing is, I upgraded to the AIP steel trigger kit (not sure if its the same as the 8mm bearing that you're getting) and the included bearing is slightly larger with the stock counterpart which makes pushing it backwards via the slide even harder. Either opt out with a smaller bearing or mod your BBU. I only tend to mod parts that I know I can have access to in case if I screw up, but luckily, I didn't. |

|

|

|

|

|

|

#60 | |

|

Quote:

The interaction point and the measurements between the hammer and sear is a bit "off" than the stock one because of the material it's made out of. It's a bit thicker. That's why the hammer bearing on the AIP set is so huge. I've installed dozens of these hammer sets alongside the 8mm bearing and they all seem to have the same story. But it may be different from his experience.

__________________

"May you fight with the strength of ten full grown men." |

||

|

|

|

|

|

||||||

| Bookmarks |

| Thread Tools | |

|

|

|